For many if not most in the biochar world, both in academia and industry, the focus so far has largely been on the use of biochar as a soil fertility booster which has the added bonus of being able to safely sequester carbon for the long-term. However markets for sequestration products are currently non-existent in many parts of the world, and where one does exist it is often voluntary, and few if any have yet officially recognized biochar as an offset product. Given that, there has been much attention paid to biochar’s value proposition in agriculture, specifically whether the potential yield increases justify the cost of using biochar. Given all the variables, not just on the biochar side, but with differences in crops, soils, weather, etc. this has been a tough proposition to prove in many cases. While new research shows that biochar may become a highly efficient low dosage carrier of plant nutrients, most agronomic trials still struggle with huge biochar amounts achieving only small yield increases. Despite 10 years of promises, farmer demand for biochar has not yet increased to a level that may sustain economic growth of biochar businesses. While the decisive nuances of which biochar blends can best help which crops in which soils gets worked out, the imbalance of atmospheric to terrestrial carbon continues at our peril.

Understanding the Potential of Biochar beyond Soil

This focus on biochar’s use as soil amendment seems unnecessarily restrictive when biochar or charcoal or pyrogenic carbon or whatever new or old name is given to the material, has so much more potential to offer in terms of both climate change abatement and environmental regeneration. I tread lightly on how the term biochar is traditionally used as I understand that many of the pioneers in the biochar world prefer to restrict the definition of biochar to its use as a soil amendment. However, the most interesting characteristic of biochar is not necessarily its potential to improve soil fertility as critical as it is to enhance soils. Rather it is biochar’s nearly unmatched versatility. Biochar can help recycle nutrients and upcycle waste. It can remove pollutants yet retain water. It can immobilize at times and catalyze at other times. It can multi-task. It can have cascading uses. Biochar can close or rebalance or detoxify different environmental cycles from carbon, to nitrogen, to phosphorus to water. Its surface area, porosity, morphology, electrical conductivity and other varied and variable characteristics lend themselves to a myriad of different end uses. This diversity of uses combined with its ability to sequester carbon for the long term can benefit farmers, foresters, factories and beyond. This is what is so exciting about biochar. This is what makes biochar as a carbon capture and sequestration strategy unique from all other sequestration technologies.

With this broader perspective of biochar a world of opportunity opens up in terms of how and how much biochar can be used to displace materials that either have a large carbon footprint or are non-renewable or are toxic or are simply too expensive. At the Ithaka Institute we refer to this perspective as the Biochar Displacement Strategy. The goal of this strategy is to identify, quantify and prioritize new uses and markets for biochar which will decarbonize and detoxify while rebalancing and regenerating eco-systems and carbon cycles. By carbonizing underutilized waste streams and customizing production parameters for different end uses, biochar could go a long, long way towards helping individuals, companies and nations to meet their decarbonization targets.

After the Paris talks there has been an increasing amount of chatter and hopefully action, on the topic of decarbonization. The Montreal Carbon Pledge, the Portfolio Decarbonization Coalition, the Deep Decarbonization Pathways Project and other more or less well-funded initiatives are educating and incentivizing investors and urban planners to cut carbon out of the supply chain in various different industries. But decarbonization cannot be limited to shifting to carbon-free electricity generation and transportation. The embodied carbon (i.e. CO2eq generated during making, moving and end of life management) or carbon footprint of a wide variety of products must also be lowered in order to meet aggressive carbon budget goals. If we look at biochar through the lens of lowering embodied carbon, there are many displacement opportunities.

Activated Carbon

Activated carbon (AC) is an obvious displacement opportunity and its use in all manner of filtration, remediation, deodorization, is an area in which biochar is already showing promise. AC comes with a heavy carbon footprint partially due to the fact that it is usually shipped long distance from Asia, it is often, though not always, made from non-renewable materials such as lignite or peat, involves the use of heavy metals for activation and is expensive. Biochar can be customized to mimic many of the properties that make AC so useful for so many different applications and generally costs much less. But in certain scenarios using biochar for filtration can have other advantages apart from being less expensive and reducing embodied carbon. When used to filter wastewater from food & beverage industries, or other non-toxic effluents that contain valuable nutrients such as can be found in aquaculture operations, the char is actually enriched after the filtration process and can subsequently be used in agriculture to enhance crop yields and of course continue to sequester carbon.

Filtration to Fertilizer

This ‘Filtration to Fertilizer’ (F2F) strategy is being jointly worked on by the Ithaka Institute, the Rochester Institute of Technology and Cornell University. So far we have tested the ability of various different biochars to filter waste water from tofu and beer production as well as dairy whey. While not quite as efficient as AC, certain biochars were able to effectively reduce Chemical Oxygen Demand (COD) and suspended solids and increase pH in the effluents. Greenhouse trials using biochar filled with tofu whey by-products showed that adding only 5% to potting mixes could boost yield substantially; 38% for lettuce and an impressive 62% for basil as compared to a standard potting mix using peat moss and perlite. If farmers could carbonize their unused agricultural waste using either combined heat and biochar technologies or even low cost kilns, then lease out the char to a local food and beverage manufacturer for filtration purposes and then reuse the filtered biochar as a slow release fertilizer, the economics of biochar use becomes very interesting. It also provides a low cost way to improve wastewater treatment which is often inadequate causing substantial negative impacts on local water bodies especially in the developing world. Due to its high cost, once used AC is often shipped off to be reactivated using high temperature thermal processes that purge residues. The F2F strategy eliminates the need for this high energy, high cost processing and also allows organic nutrients to be put back in the soil thereby boosting food security.

This is but one example of potential cascading uses for biochar – where biochar can be used more than once before being put in the ground. Another cascade where biochar could displace AC but in a gas-phase adsorption scenario is with hydrogen sulfide, a hazardous, not to mention smelly, by-product of natural gas production, anaerobic digestion, landfill gas, municipal solid waste plants and other sources. Researchers in Canada showed that using activated biochar from manure derived digestate could successfully sorb H2S and then be used as organic sulfur fertilizer replacing synthetic sulfur (Zhang et al., 2016). Their initial trials found that the sulfachar increased biomass in corn from 31 – 49% compared to corn grown using a chemical sulphate fertilizer. Other sulfur scavenging technologies exist but the sulfur often ends up ultimately being landfilled or is merely fed to microbes that can render the H2S harmless thus wasting valuable nutrients.

Concrete

Another high carbon footprint material that biochar could help to decarbonize is concrete. The use of biochar in concrete recipes can have some very positive effects beyond just lowering the embodied carbon including improved insulation and humidity control (Schmidt, 2014). It can also reduce the weight of concrete which can be useful in some but not all applications. Researchers in Europe even found that it can reduce pollution from nitrous oxides, a toxic gas, when sprayed onto tunnels or car parks (EU-COST Action, 2015). And somewhat surprisingly it can even improve fire resistance (British Biochar News, 2015) as compared to concrete without biochar!

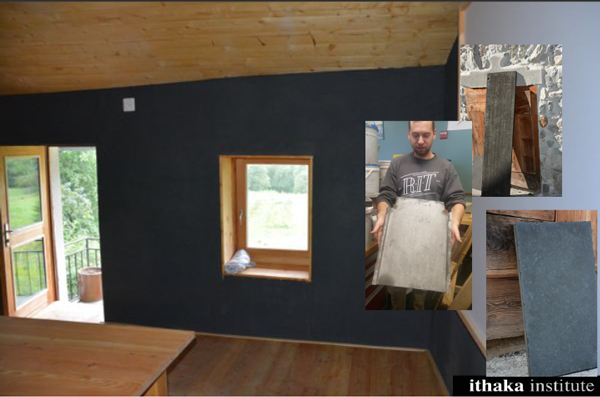

Figure 1: Biochar is an extremely versatile building material not only being used in plaster but also in concrete, bricks, insulation materials and mixed with most types of building binders.

Research out of Malaysia (Laili et al., 2015) has shown that using biochar with cement can help immobilize low level radioactive wastes. Organic ion exchange resins are often used to decontaminate radioactive wastewater from nuclear power plants. Once these resins have been used, the material is referred to as ‘spent resin’, and must be managed as hazardous waste. One such management technique is to immobilize resins in cement. Cemented spent radioactive waste tends to swell after contact with water which can result in the fracture of cemented spent resin. Initial trials showed that biochar cement passed both water resistance and compressive strength tests and is currently being tested to see how biochar compares to using other admixtures in terms of reducing leaching of radionuclides from cemented spent resin. Recipes using up to 18% biochar, and nearly 15% less cement and 12% less water have shown promising results. The world has 444 nuclear power plants with 63 new plants under construction. 90% of the nuclear waste from each plant is considered low level which could be stabilized using this method. Not only could an increasing amount of carbon be sequestered if biochar was used as the gold standard for immobilizing low level radioactive waste from power plants and other sources, but the radioactive waste could be ensconced with a higher degree of safety.

Replacing Non-renewables

Looking through the lens of non-renewables, biochar could potentially displace or at least substantially scale down the use of a variety of materials that are mined or drilled or vacuumed up from the earth or ocean. Materials such as peat moss which is used extensively in the world of horticulture. Or precious metals used in microbial fuel cells (Huggins et al., 2014). Even sand, which seems so plentiful yet is being heavily harvested from rivers and oceans to feed our concrete addiction could at least partially be displaced with biochar.

Desiccant

Beyond its use in concrete, if quartz sand is washed, scrubbed, acid-leached and transported to and fro it is transformed into silica gel, a desiccant used to control moisture and mold. Tens of thousands of tons of desiccants are manufactured every year and it is often thrown away after just a single use. Wouldn’t it be better if farmers that need to ship fruits or vegetables long-distance make their own desiccants just by carbonizing unused agricultural waste? Once its dehumidifying duties are done, the biochar packets can be safely tossed into a compost pile as a carbon source. More cascading uses and definitely less mining and landfilling!

Carbon Black

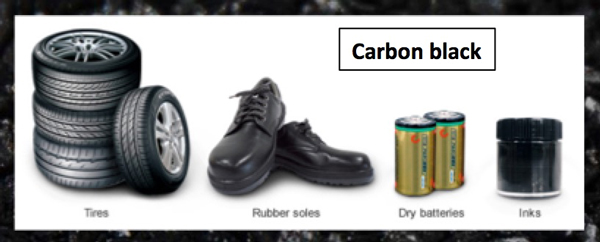

Another non-renewable based product that biochar could displace is carbon black (CB) which is made from sour gas, a highly polluting form of natural gas. CB is a common ingredient in tires, conveyor belts, hoses, footwear, weather stripping, car bumpers. It is also used as a color pigment for inks and has found uses in films, adhesives, magnetic tapes, garbage bags, agricultural plastics and so on. Market demand for CB was estimated at more than 13 million tons in 2015 and is expected to increase by 3.74% per annum over the next five years (Smithers Rapra 2016). Imagine the impact if we can design the right kind of biochar to displace this material. Researchers from the USDA have found that high carbon, low ash biochar could potentially provide up to 40% of the filler for tires without any significant loss in tensile strength. (Peterson, 2016). Depending on the grade of CB, prices can range from $2,500 to $4,500 per ton, so biochar can definitely compete well on price. If these biochar-based products end up in a landfill at the end of their life as many of the CB products do, the biochar will continue to do good, by sequestering carbon and potentially sorbing toxins in landfills.

Figure 2: More than 13 Million tons of carbon black is used in many types of consumer goods.

If we could find a way for biochar to displace certain rare earth metals, which are used extensively in everything from fuel cells to fiber optics, there are a lot of industries that would happily switch to using a highly renewable and sustainable material which isn’t subject to price instability nearly as much as rare earth metals are.

Supercapacitors

Biochar could also play a key role in energy storage in the form of supercapacitors. Biochar based supercapacitors using pyrolyzed coconut husks have been in existence since the 1990s but new research is looking at other feedstocks and post production technologies to further enhance surface area and storage capacity (Harris et al., 2016). Supercapacitors are complementary to slow charging and discharging lithium batteries and can be integrated into smart grids, electric cars and many other devices to help regulate power supply and decrease the need to have excess batteries to deal with peak demand scenarios.

Animal Feed

Then there is the lens of displacing toxic or environmentally harmful materials with biochar. In this category I include materials such as the prophylactic use of antibiotics in animal feed to boost feed conversion and maintain herd health. While already forbidden in some EU countries, it is still common practice in most countries to use antibiotics to improve margins for animal operations. This is despite the fact that this excessive use of antibiotics has serious long term negative impacts on water and soils used to grow food as well as other implications for human health in the form of anti-biotic resistant bacteria. Biochar use in animal feed is one of the most asked about areas of biochar usage amongst biochar producers in the US and in Europe it already is the most common initial use for biochar. Although more research is needed, preliminary studies have shown that it can boost feed conversion rates and improve herd health for cattle, poultry, hogs and fish fish (Schmidt et al., 2016; Toth and Dou, 2015). Pet owners are also using it to mitigate unwanted pet odors!

Micro-Beads

Plastic micro-beads are another eco-hazard which can wreak havoc when they end up in watery eco-systems, which is not uncommon as many wastewater treatment facilities are unable to filter out these tiny particles. These micro-beads are added to cosmetics and even toothpaste for their exfoliating abilities. As we all know biochar can be pretty abrasive, so why not use biochar instead of plastic for materials that we slather onto our bodies. It might even help detoxify to some extent as activated carbon has been used for many, many years both internally and externally to rid the human body of toxins!

Biochar Markets

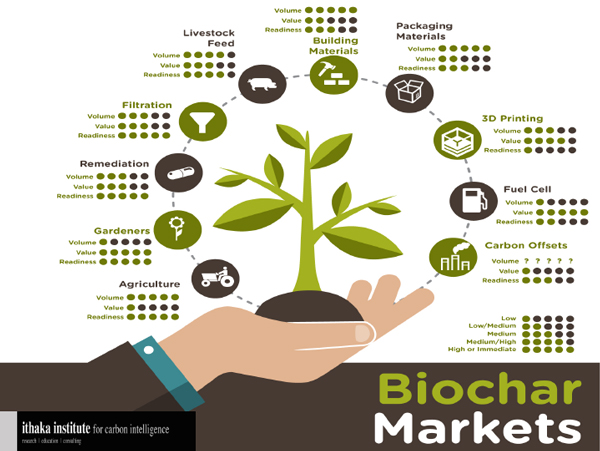

There are many other biochar displacement possibilities some of which are outlined in Figure 3. Some markets, such as fuel cells, may provide higher returns yet lower volumes for biochar producers as compared to agricultural uses. Others, like biochar in 3D printing and in packaging materials, may take a bit longer to develop since little research has been done to date. Fossil fuel based carbon fiber 3D printing is already happening but the main barrier seems to be cost. At $16/lb (3ders.org, 2016) that is understandable, so customized biochar may offer both a cost & carbon footprint advantage. We just need to start collaborating with those businesses or academics that are already in this space to educate them on the versatility and sustainability of biochar.

Figure 3: Biochar markets and future displacement possibilities.

Food Storage

Research on the use of biochar in packaging is still in the very early stages but researchers in China, Australia and the US are testing its use in biodegradable plastics used in food storage. They have found that adding up to 7.5% biochar by weight improves tensile strength by more than 50% and lowers degradation caused by UV irradiation. If we could use this type material for agriculture plastic sheeting, it might end up being an effective way to deliver biochar to soils, if it can be plowed under after its initial use as a weed barrier or as a means of warming soils or saving water. More cascading uses, less waste and more carbon sequestered.

Conclusion

My hope is that this expanded perspective of biochar uses and markets has highlighted the enormous potential of biochar in the new bio-based circular economy. It is time to go beyond the traditional thinking of biochar as a soil amendment. We must be more expansive and more creative in terms of thinking about how and where carbonized biomass can be used, what it can displace and what industries it can help decarbonize. The versatility of biochar and the potential that this versatility suggests requires a whole new level of collaboration of experts in a multitude of new fields. While the first generation of biochar researchers included soil scientists, agronomists, plant nutritionists, plant biologists, we now need to expand on that and include new networks of experts from material science, electrochemistry, civil engineering, biological economics, electrical engineering, veterinary sciences, waste management, climate science, public policy to name just a few, in order to achieve the true potential of biochar to restore and regenerate and rebalance. We also need to move beyond academic research silos and beyond patent driven, closed door corporate thinking. We need collaborative, dare I say open-source teams working together across borders and across disciplines.

Asking the question ‘What else can biochar displace?’ is likely to lead us to products and markets that we haven’t even begun to consider. Asking the question, ‘how much could a city or an industry or a country reduce its carbon footprint by carbonizing ALL underutilized organics and utilizing ALL by-products of pyrolysis or gasification’ could lead us to amazing new closed loop industrial design scenarios where nothing is wasted and everything is upcycled. That’s the ultimate goal of the Biochar Displacement Strategy and I hope all of you will be a part of creating that kind of future for biochar!

REFERENCES

3ders.org (2016) The strongest players in carbon fiber 3D printing today, http://www.3ders.org/articles/20160229-the-strongest-players-in-carbon-fiber-3d-printing-today.html, retrieved 25th March 2016

British Biochar News (2015), Issue II: http://www.britishbiocharfoundation.org/wp-content/uploads/BritishBiochar-Newsletter-Autumn-2015.pdf, retrieved 15th October 2016

EU-COST Action on Biochar (2015): Summery of the Final EU-COST and ANS Biochar Symposium 2015, http://cost.european-biochar.org/en/ct/176--Summery-of-the-Final-EU-COST-and-ANS-Biochar-Symposium-2015, retrieved 15th October 2016

Harris, Mark, (2016) Beyond batteries: This technology could revolutionise energy, New Scientist, Magazine issue 3099, 12 November 2016, https://www.newscientist.com/article/mg23230990-500-beyond-batteries-this-technology-could-revolutionise-energy/, retrieved 15th November 2016

Huggins, T., Wang, H., Kearns, J., Jenkins, P., Ren, Z.J., 2014. Biochar as a sustainable electrode material for electricity production in microbial fuel cells, Bioresour. Technol. 157, 114–119.

Laili, Z., Yasir, M.S., Wahab, M.A., Mahmud, N.A., Abidin, N.Z., 2015. Evaluation of the compressive strenght of cement-spent resins matrix mixed with biochar, Malaysian J. Anal. Sci. 19, 565–573.

Peterson, S (2016) Biochar in Carbon Black replacement: what we’ve seen and where we are going, IBG meeting, October 10, 2016, http://bit.ly/2gj0vmk

Schmidt, HP, Kammann, C.I., Gerlach, A., Gerlach, H., 2016. Der Einsatz von Pflanzenkohle in der Tierfütterung, Ithaka J. 5, 364–394.

Schmidt HP, 2014, The use of biochar as building material , the Biochar Journal 2014, Arbaz, Switzerland, www.biochar-journal.org/en/ct/3, Version of 12th May 2014, Accessed: 27.11.2016

Smithers Rapra (2016) Smithers Rapra Forecasts Carbon Black Markets To Grow At 3.74 Percent CAGR, http://www.smithersrapra.com/news/2016/july/carbon-black-market-forecasts, retrieved 15th October 2016

Toth, J.D., Dou, Z., 2016. Use and Impact of Biochar and Charcoal in Animal Production Systems, in: Agricultural and Environmental Applications of Biochar: Advances and Barriers. Soil Science Society of America, Inc., pp. 199–224.

Zhang, H., Voroney, R.P., Price, G.W., White, A.J., Azargohar, R., Dalai, A., Bagreev, A., Bandosz, T., Bagreev, A., Bandosz, T., Bagreev, A., Adib, F., Bandosz, T., Bandosz, T., Bandosz, T., Bashkova, S., Baker, F., Wu, X., Armstrong, T., Schwartz, V., Bouzaza, A., Laplanche, A., Marsteau, S., Dalai, A., Tollefson, E., Farrell, M., Macdonald, L., Butler, G., Chirino-Valle, I., Condron, L., Guo, J., Luo, Y., Lua, A., Chi, R., Chen, Y., Bao, X., Xiang, S., Hale, S., Alling, V., Martinsen, V., Mulder, J., Breedveld, G., Cornelissen, G., Huang, M., Yang, L., Qin, H., Jiang, L., Zou, Y., Keiluweit, M., Nico, P., Johnson, M., Kleber, M., Lebrero, R., Bouchy, L., Stuetz, R., Munoz, R., Primavera, A., Trovarelli, A., Andreussi, P., Dolcetti, G., Ros, A., Montes-Moran, M., Fuente, E., Nevskaia, D., Martin, M., Sarkhot, D., Ghezzehei, T., Berhe, A., Taghizadeh-Toosi, A., Clough, T., Sherlock, R., Condron, L., White, A., Kirk, D., Graydon, J., Xiao, Y., Wang, S., Wu, D., Yuan, Q., Xu, X., Cao, X., Zhao, L., Sun, T., Yang, T., Lua, A., Zhang, H., Voroney, R., Price, G., 2016. Sulfur-enriched biochar as a potential soil amendment and fertiliser. Soil Res. 110, 413–421.

Multipurposed Biochar Nature of Its Slow Uptake

People are looking for focused single silver-bulleted answers to our global woes. The multi-tasked biochar does not fit this kind of profile. I am not an academic and have problems discerning value in biochar, because of this lack of focus and multi-disciplinary perspective to appreciate biochar power. The significant figures in the value of biochar in the production in basil, for example, (a favourite herb of mine in the home-made production of pizza) would be a good reason for me to use it - but then there are a multitude of other uses that may well be compelling in themselves, but as a group, dilute its value via diffusion.

I am sure there are producers/users of biochar for filtration of water, as a single use example, who would be able to raise awareness of the value of Biochar and encourage wider use and develop market penetration for this incredible product. There has to be an extensive effort to market this product, beyond academic reasoning, to make people aware and to develop the market demand. Perhaps IBI could widen its perspective to participate in this endeavour.