From 2000 to 2019, global plastic production doubled from 200 million to 400 million tonnes per year. According to projections of the Organization for Economic Co-operation and Development (OECD), it will triple again by 2060, reaching around 1.2 billion tonnes of plastic annually.

Plastics are principally made from fossil carbon and contain, on average, 80% carbon. Therefore, 1.2 billion tonnes of plastic correspond to approximately (1.2 t * 80% C * 44/12 =) 3.5 gigatonnes (Gt) of CO₂e emissions that would be released when the plastic products are incinerated at the end of their lifecycle. In addition, 2.7 tonnes of CO₂e are emitted during the production of each tonne of plastic.

With the expected annual production of 1.2 billion tonnes of plastic, emissions of around 6.2 billion tonnes of CO₂e (6.2 Gt CO₂e) would be caused either through waste incineration or, more slowly, waste dumping. Recycling can delay the process, but it cannot avoid the eventual emission of the carbon that plastic is made from.

The UN, EU, IPCC, and the Paris Climate Agreement aim to reduce global net emissions to zero by 2050. This means that no more greenhouse gases may be emitted than are removed from the atmosphere. To achieve this, emissions must be reduced to no more than 10% of 1990 levels, with the remainder being offset by carbon sinks. However, 10% of the 1990s global emissions amount to 2.3 Gt CO₂e, which is nearly three times less than the plastic-related emissions expected in 2060.

The projected emissions from the plastics industry illustrate how unrealistic many legally mandated climate targets are. In addition to the plastics industry, construction, steel, and chemical industries also depend heavily on fossil carbon and make the 90% emission reduction goal wholly unachievable without fundamental transformations of these critical industries.

Climate protection is not just about generating renewable electricity or replacing the fuel pump with a turbocharger. Even more crucial is a fundamentally new industrial policy that rethinks, actively supports, and regulates the production processes for plastics, concrete, asphalt, fertilizers, and steel.

If even countries like Germany and Switzerland have no plan to convert the plastics industry to run on recycled carbon, then the goal of limiting emissions to 10% of 1990 levels is unattainable.

However, there is something that can be done. The first industrial plastics were not made from crude oil, but from biomass. Celluloid, for example, was produced from cellulose treated with a mixture of nitric and sulfuric acids, followed by camphor as a plasticizer (source). Today, plastics are once again increasingly being made from biomass. However, to fully liberate mass-market plastics from crude oil dependency, a more abundant and chemically standardized carbon source must be tapped. CO₂ extracted from the atmosphere emerges as the greatest opportunity. CO₂ is omnipresent, pure, and chemically identical regardless of where it is captured. Thanks to increasingly cheap solar power, methanol produced from CO₂ is becoming more cost-effective than conventional petrochemistry.

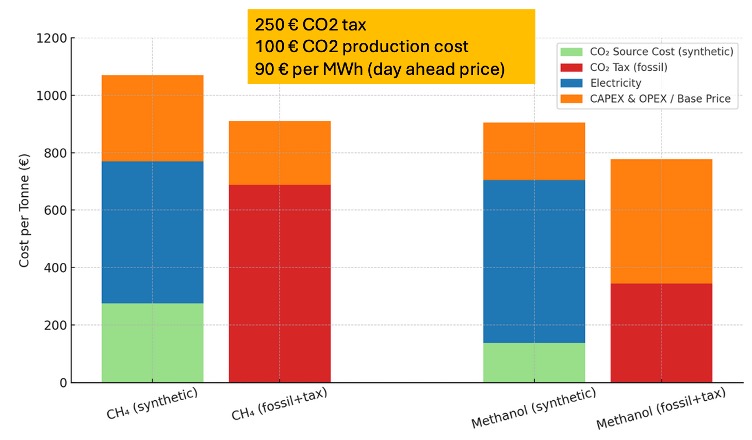

Figure 1: Cost comparison of CH₄ and methanol produced from recycled CO₂ (synthetic) versus natural gas. The comparison assumes a CO₂ tax of €250 per tonne, lower than the €325 per tonne in climate impact costs calculated by the Swiss government. It also accounts for production costs of €100 per tonne for flue gas separation from waste incineration (Bertone et al., 2024), and an average day-ahead electricity price of €90 per MWh in Switzerland. However, with solar electricity prices falling below €10 per MWh—as seen in the Shuaibah project in Saudi Arabia—CO₂ taxes as low as €120 per tonne CO₂e are sufficient to make methanol from recycled CO₂ cost-competitive with methanol from natural gas.

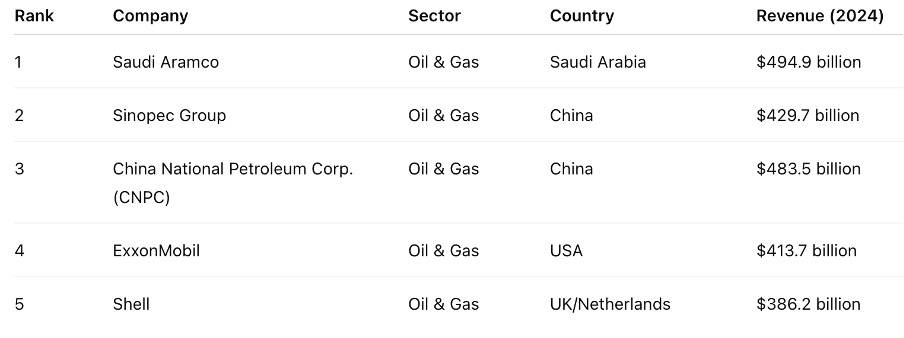

Leaving aside the question of whether the world truly needs three times more plastic—and whether it will even be capable of collecting and disposing of the enormous waste volumes that result—producing plastics from recycled CO2 presents a tremendous industrial opportunity and the chance for the world to free itself from the five largest and most powerful companies on the planet (see Figure 2).

Figure 2: The five most powerful and highest-revenue industrial companies in the world (only the major internet companies have higher valuations based on market capitalization). Source: Fortune Global 500 (2024).

Oil and gas are available in only a handful of countries, which has placed most other nations in structural dependence on petro-dynasties. Carbon from the atmosphere, by contrast, is equally and universally available in every country in the world. It is merely a question of the available renewable energy to recover and process CO₂, either from the air or from industrial emissions. Capturing CO₂ from the flue gases of waste incineration is the most immediate solution, both technically and energetically. The cost for recovering CO2 from incineration is only around 100 €/tCO2 (Bertone et al., 2024). It is an unparalleled waste of resources to simply release valuable carbon into the atmosphere instead of processing it locally and returning it to industrial use.

CO₂ can be synthesized with green hydrogen (produced via electrolysis using solar power) into methane (CH₄) or—more efficiently—directly into methanol (CH₃OH) using a metal catalyst. While methane is chemically identical to fossil natural gas, methanol is the most important precursor for all sorts of materials and compounds in the chemical industry. It can be seamlessly integrated into existing petrochemical processes for the production of plastics, pharmaceuticals, carbon fibers, and synthetic fuels.

Instead of importing oil and gas from Russia, Arabia, Nigeria, the United States, or Venezuela—and generating additional emissions through transport, storage, and pipeline losses—countries like China, Germany, and Switzerland could shift their plastics and pharmaceutical industries to domestically captured CO₂. Retrofitting all waste incineration plants with CO₂ capture would be a decisive first step.

The promotion of CO2 recycling, funded and co-financed by the EU and governments through emission taxes, would be the most efficient form of modern economic transformation. It reduces emissions and pollutants, strengthens national sovereignty over raw materials, and creates investment incentives for regional value creation. Excess wind and solar power could finally be harnessed for productive purposes rather than curtailed to preserve grid stability. It would be the decisive step toward a circular carbon economy. In a future where robots and artificial intelligence displace the service economy, securing access to domestic raw materials will determine the well-being or decline of nations.

Circular Carbon Economy

This is pure CCE (Circular Carbon Economy), McDonough&Duarte put it on paper at the G20 2020 already, and Braungart just delved into it recently in Madrid. Avoiding plastics to end up in traditional incinerators - or even long term worse - as litter in the oceans, is a good Plan. This is what McDonough defined as FUGITIVE EMISSIONS, in his New Language of Carbon proposal. The Green Hydrogen part is the main question mark for me, as well as the whole system effectiveness, because from a WLC (whole life carbon) standpoint, all C - included the one embedded in the equipments - should be brougth up into the equation. Having said that, if CDR can be done not only for the Biosphere (e.g. Biochar) but for the Technosphere (e.g plastic fossil fuel-free products), without the burden of litter and hazardous chemicals leakage (watch this, it's critical too), then we might have a Plan. Tks for the release Mr.Schmidt.